What should we pay attention to in the process of manufacturing PU leather?

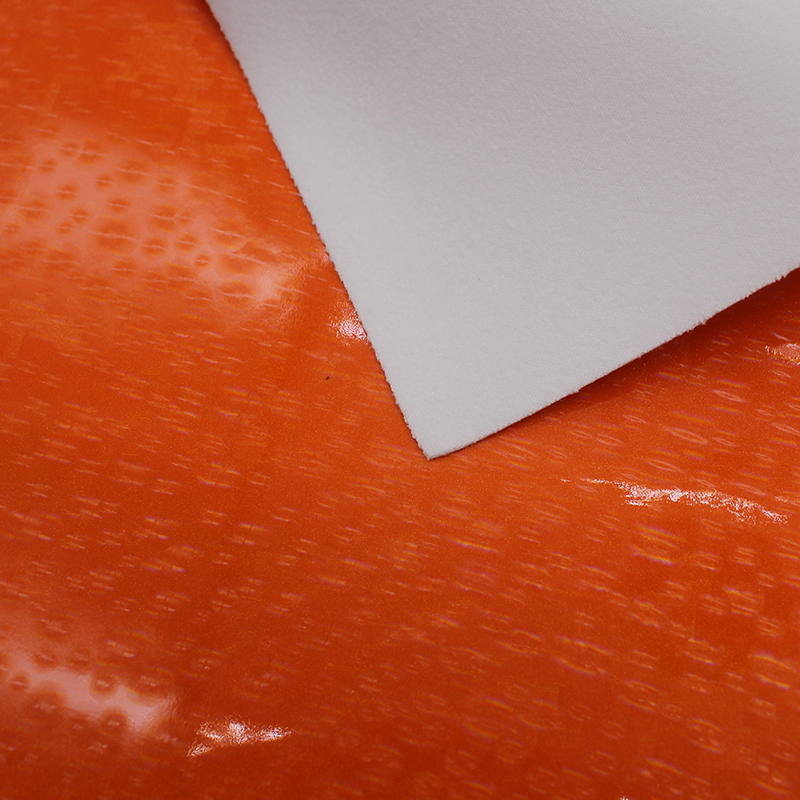

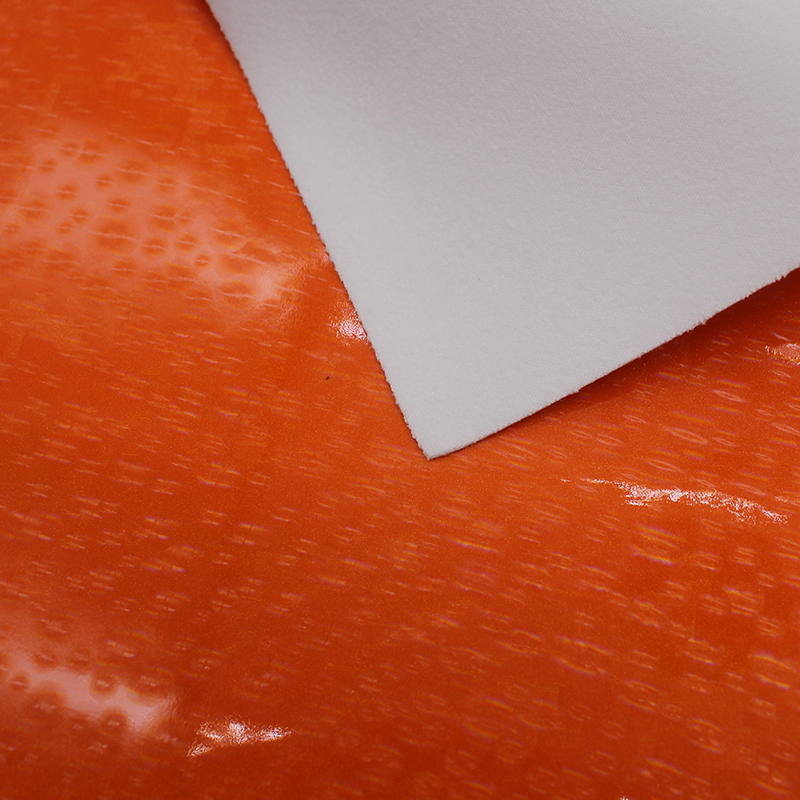

PU leather is a synthetic leather similar to genuine leather, which is waterproof and breathable.

In the process of manufacturing PU leather, there are a few precautions to share with you:

1. The surface of PU leather is astringent and not easy to sew. Silicone oil is not recommended (difficult to volatilize). Detergent can be added to water instead of silicone oil. In the process of manufacturing PU leather, plastic pressure angle should be used when cutting the stop and cutting line, and metal pressure angle should not be used to avoid damaging the surface of the fabric. Cardboard or film should be placed on the sewing; when cutting the wide stop and cutting line, because PU leather has elasticity and is easy to twist, it can be assisted by a pressure roller.

2. The fabric of PU leather has weak folding and ironing properties and is not resistant to high temperatures. Ironing should be reduced during the manufacturing process. If an iron is used, a layer of cloth should be used.

3. The finished products of PU leather need to be kept dry during storage to avoid mold.